Difference between revisions of "POP Kiosk"

(→Kiosk) |

|||

| Line 104: | Line 104: | ||

If you want to display your interactives in a physical space, like a gallery or as part of a pop-up exhibit, you will need a kiosk computer system. You can follow our guide to build the POP prototype kiosk. The total per-unit build cost per kiosk is $220. This low-cost and modular hardware configuration allow the kiosk to be assembled and deployed with minimal resources, while offering the flexibility, accessibility and maintainability to engage a variety of audiences in different learning contexts. | If you want to display your interactives in a physical space, like a gallery or as part of a pop-up exhibit, you will need a kiosk computer system. You can follow our guide to build the POP prototype kiosk. The total per-unit build cost per kiosk is $220. This low-cost and modular hardware configuration allow the kiosk to be assembled and deployed with minimal resources, while offering the flexibility, accessibility and maintainability to engage a variety of audiences in different learning contexts. | ||

{{See|Creating a POP Kiosk}} | {{See|Creating a POP Kiosk}} | ||

== Using a POP Kiosk == | |||

=== Creating a CLIO Exhibit === | |||

{{Stub}} | |||

=== Creating a Wireless 3D Printer Server === | |||

{{Stub}} | |||

== References == | == References == | ||

Revision as of 23:30, 19 April 2022

Overview

Purpose

Development Process

Technology

Fabrication

Printer

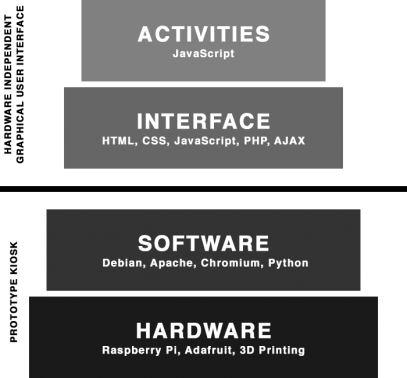

For this project, we used a Creality CR-10 Mini 3D printer. It is a consumer-grade, entry-level 3D printer for both amateurs and professionals. It uses the Fusion Deposition Modeling technique of printing that fuses extruded filament together, layer by layer, to create a three-dimensional object.

This entry-level 3D printer cost around $350 and is an excellent investment for anyone who is new to 3D printing. The underlying source code powering this printer is open-source, allowing advanced users to tweak, alter and upgrade their printer with available open-source add-ons and expansion packs.

This printer can be divided into three primary parts: the print head, the print bed, and the control box.

The Creality CR-10 mini uses a motorized gear (known as a Bowden extruder) to take in the solid filament from the spool. The Bowden extruder pushes the filament through a tube and into the printhead, progressively heating the filament until it turns to an amorphous plastic.

While heating and extruding measured amounts of filament, the print head moves along the X- and Z-axis, while the print bed moves along the Y-axis, to print two-dimensional layers that are stacked on top of each other to create three-dimensional objects. Printing large objects can take many hours, which is why the print bed is heated to keep the filament from cooling and becoming detached.

Filament

For the prototype kiosk, we used two different types of printer filaments to fulfill different needs. We used a Polypropylene filament to print the rigid case and mount accessories, as well as a flexible TPU for anti-slip grips.

Hardware

Computer

The Raspberry Pi single-board computer was specifically picked for several reasons. The Raspberry Pi Foundation, who create and maintain the Raspberry Pi computer, are a non-profit organization who offer coding lessons to schools. Owing to their open-source nature, the Raspberry Pi computer has undergone rigorous testing through the Foundation, as well as the open-source community and demanding consumer market. These systems are still extremely affordable, ranging from $5 to $55 based on the included features.

An important consideration was the long-term feasibility and maintainability of the computer. The Raspberry Pi Foundation was one of the first single-board computers available on the consumer market and, while there are now more powerful alternatives, they have proven their stability throughout the technological boom surrounding the Internet of Things, both as a product and an institution.

Our prototype kiosk is powered by a Raspberry Pi 4B, which is considered the flagship model of the Raspberry Pi. It includes a 64-bit quad-core processor running at 1.5GHz, with metal heatsink and 2GB of RAM. This allows the CLIO interface to run smoothly with all of the included activity types. It has a unit cost of $45.

The Raspberry Pi 3B+ computer is a previous generation model and approximately a third as powerful as the Raspberry Pi 4B. The Model 3B+ has been tested to be a viable solution for use with a touchscreen while having minimal interface lag and adequate heat management.

Both models are available and fully supported by the Raspberry Pi Foundation. Due to the many different technical applications and customers using the product, the Raspberry Pi Foundation has stated that both models will remain in production until at least January 2026[1].

Touchscreen

For the CLIO prototype kiosk, we decided to use the official Raspberry Pi 7” touchscreen display. It has guaranteed out-of-box support with the Raspberry Pi when used with the official Raspbian operating system, as well as many other distributions of Linux.

The display receives its signal directly through a special DSI (Digital Serial Interface) cable connected to the Raspberry Pi computer. This port decreases the overall footprint by removing the use of a bulky HDMI cable. We have chosen to power the display through the GPIO (General-Purpose Input and Output) port. The display can also be powered through a MicroUSB cable should you need the GPIO port for other add-ons, such as an audio HAT (Hardware Attached on Top).

Additionally, this display is glass with a ten-finger multitouch screen, while most other affordable displays are plastic with a one-finger resistive screen. This creates a much more versatile experience. The glass screen lends to a pleasant and more familiar usage experience, while also allowing for easier cleaning with a disposable sanitary wipe. When used with adequate quality USB cables, both the Raspberry Pi and display can be powered through one USB power supply.

While the Raspberry Pi Foundation has made no official obsolescence statement guaranteeing the production of this product, it has been available on the market and supported since 2015.

Storage

We use a Micro SDHC card with a storage space of 16GB and speed of UHS-I/Class 10.

Power Supply

We use the Canakit USB-C Raspberry Pi 4 power supply with additional overhead power (5.1V vs 5V) and increased amperage (3.5A vs 3.0). All USB cables are at least 20AWG to help alleviate voltage drops.

Software

Operating System

A primary objective of CLIO was keeping as much as we could open-source. This increases community involvement, decreases licensing fees, and helps to ensure the continued development of other projects like it. We have chosen to use a Debian-based Linux operating system called Rasperry Pi OS Lite. This is the official Raspberry Pi Operating System without a desktop Graphical User Interface.

Web Server

We used the Apache2 HTTP web server.

Web Browser

We used the open-source Chromium web browser. This browser is the major structural foundation of the wildly popular Google Chrome. Chromium maintains the major features of Google Chrome, but does not contain any direct integration into Google’s services. We chose this browser because it has innate support for a kiosk-mode that disables access to the operating system and a collection of useful command line configuration options.

Kiosk

The POP kiosk is made from a collection of modular parts that can be printed separately and assembled into different configurations based on your specific needs and application.

Case

This is the main case that protects the Raspberry Pi computer and touchscreen display. It attaches directly to the four screw holes on the Raspberry Pi official display using M3 screws. This case has an integrated 75x75mm VESA-compliant M4 mount holes. It can also be used with a 3D-printed mount attachment that can attach to the back, top or bottom side of the case. This attachment is compatible with the popular Modular Mounting System[2]. We include a C-clamp, durable foot and 3D printer frame attachment. There is a maintenance port that allows access to the USB and ethernet ports. There are holes for panel mounting a USB-C slot to reduce wear on the Raspberry Pi itself. There is an optional 30mm fan to keep the kiosk cool during operation, as well as plenty of air vents.

Protection

Collar

The collar protects the exposed edges of the Raspberry Pi touchscreen display, decreasing the chances that the kiosk screen will be damaged from minor bumps and falls. It is printed in two parts and held together by M2 screws.

Bumper

The bumper also protects the exposed edges of display, but it is printed as one part with a soft and flexible TPU filament. When printed with specific infill settings, it can provide additional protection to bumps and falls. This bumper is used instead of the collar and was created for use in mobile pop-up exhibits.

Cover

The cover provides protection to the front of the kiosk display by attaching directly to the collar or bumper. This cover was created to provide protection to the glass screen during transport and storage. Attaching foam to the cover is optional but will provide additional impact protection.

Mount

Modular Case Adapter

This adapter is attached to the back, top or bottom of the kiosk using two M5 bolts. It can be used with any accessories created for the popular Modular Mounting System[2]. It is printed in two parts and attached together with an M5 bolt and optional glue. The mount can be used with a two- or three-prong adapter.

Arm

There are 30mm, 60mm, 90mm 150mm and 240mm arm attachments for the Modular Mounting System. These can be used to extend the length of the mount system, but caution should be used to verify that the kiosk is fully supported. This includes axis changers and prong adapters.

Foot

The foot is used to display the kiosk on a flat surface, such as a table or shelf. It is printed in two parts then attached together with an M5 bolt and optional glue. The foot can be used with a two- or three-prong adapter. The foot can be used with suction cups to more securely attach to sheer surfaces, such as glass or polished stone. Additionally, 3D printed TPU or third-party anti-slip grips can be attached to the bottom.

Thumbscrews

The thumbscrews are used with standard M5 bolts to make it easier to tighten and loosen the display for repositioning.

Creating a POP Kiosk

If you want to display your interactives in a physical space, like a gallery or as part of a pop-up exhibit, you will need a kiosk computer system. You can follow our guide to build the POP prototype kiosk. The total per-unit build cost per kiosk is $220. This low-cost and modular hardware configuration allow the kiosk to be assembled and deployed with minimal resources, while offering the flexibility, accessibility and maintainability to engage a variety of audiences in different learning contexts.